It’s time for the simple part, let’s review what we gathered so far and jump to conclusions:

- Your overall time of loading from empty to 180bar = 100%

- Time without pump slowing down = % of Brake Accumulator capacity loss

- Time of accumulator pump topping-up = pressure increase from 140bar to 180bar

- Time of load from empty to pump starting to slow down = faster load due to faster pump speed

- Maximum pump rev loss = approx. 40% at the end of load cycle, losing the revs while pressure increases

Now, overall time minus time without compression would be too easy as the brake liquid flows faster without pressure from membrane and goes slower while the pressure increases, so the ultimate factor will be somewhere close to 0.7, so time running without pressure = 1 while the time pump slows down due to increasing pressure = 0.7 to make it flat and easy in terms of volume. So we need to find time were compression starts evidently and apply 1.0 to pre-compression time and 0.7 to compression time Then we can count reference of top-up time as the jump from 140bar to 18bar and calibrate our calculation. Then we can divide time while running with no compression by the overall time of pump action to get our theoretical percentage of Pressure Accumulator Sphere’s performance loss. Plus measurement uncertainty of 10%. I know, it sounds simple. To simplify even more we need to apply likelihood of issue occurrence for three main components of XJS brake accumulator...

I was trying to describe a formula allowing calculation of approximate performance loss of each brake accumulator with data gathered with use of watch and your ears. After a while I realised that description above will be sufficient for those able to do it and will keep away those who can’t. For safety reasons – let’s keep it that way.

Conclusions:

3.1. What’s most important:

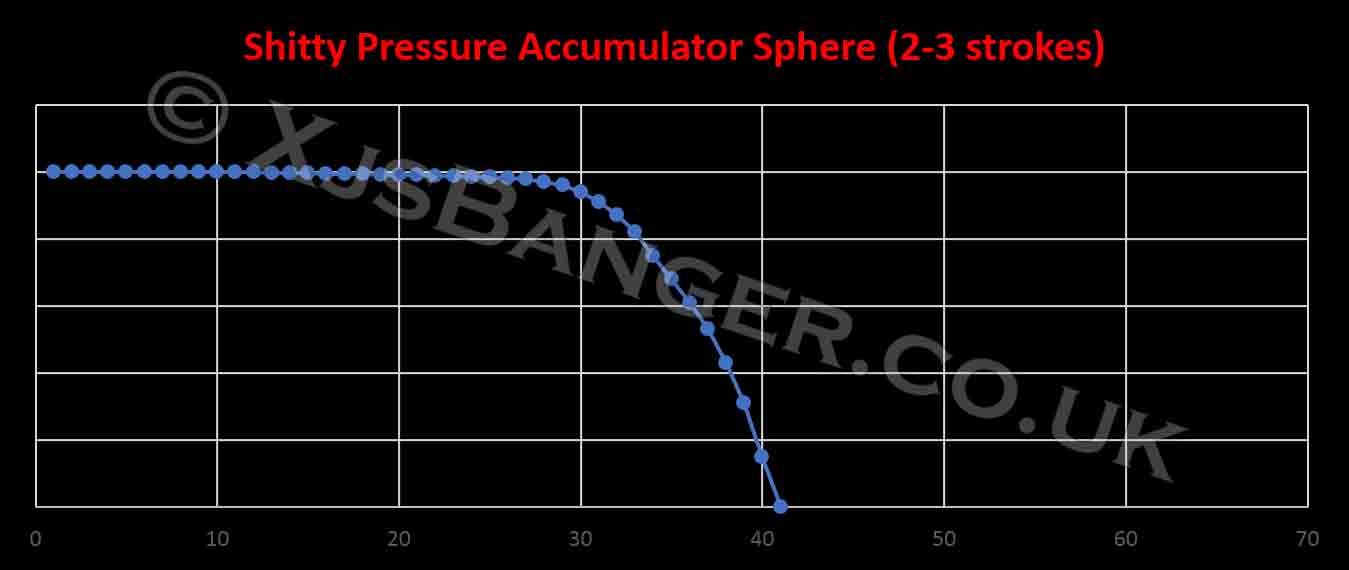

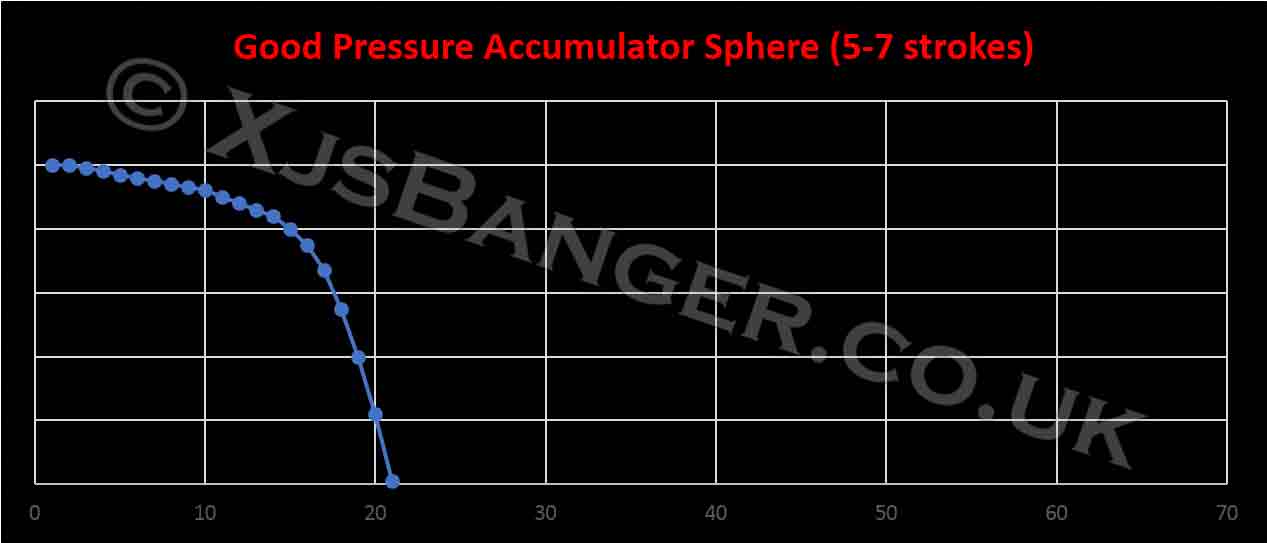

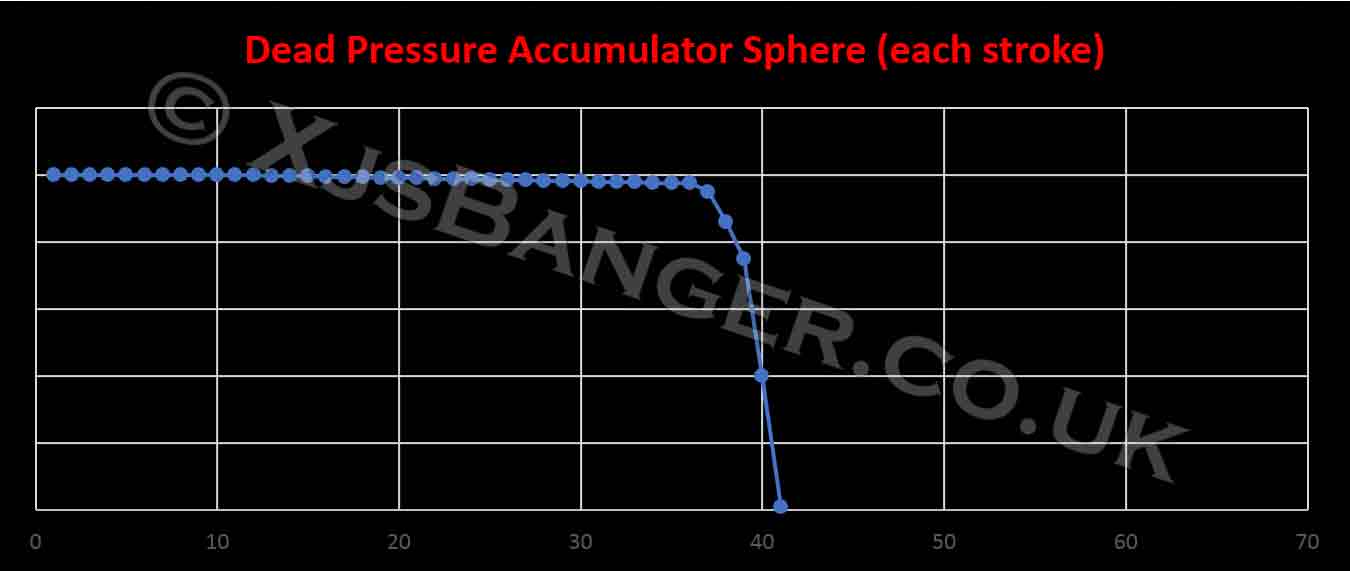

UNIFORM, CONSTANT DROP IN PUMP REVS EXPRESSED WITH SOUND “EEEEEIIIIIIUUUUUOOO” OVER ENTIRE TIME OF LOAD-FROM-EMPTY OPERATION (see graphs below)3.2. Overall pumping time doesn’t matter. Before you’ll start bullshit talk about overall pumping time – please remember that those pressure pumps were made for Leyland and installed in British cars. I can only imagine tolerances on those flying around on assembly with smile and “QC PASSED” stamps fuming from over-usage and abuse. You will get massive differences in time (required to load the accumulator sphere) between the cars due to the physics/tolerances involving eccentric operation of the pump.

3.3. Short top-up time (4-6s) confirms good condition of the sphere – as long as “unload test” goes well (see: “Diagnose Pressure Accumulator Sphere first”)

3.4. If your Brake Accumulator pump kicks in after 3-4 strokes - performance of the whole assembly is very good. If you're making only two strokes - be prepared to have spare Pressure Accumulator Sphere and o-ring required for replacement.

3.5. If something works - don't touch it with your salad fingers. If you are unable to control yourself - buy brand new sphere and keep it in your wardobe until your XJS will kindly ask you for the new one.

...What? You want it even more simplified?! No way. Can’t do it. Or maybe. See the graphs below:

X axis

(for UK residents: horizontal length of the chart) = example time, don’t treat it as reference.

Y axis

(for UK residents: vertical length of the chart) = example drop in pump revs (that can be assessed by your ears only I’m afraid…).