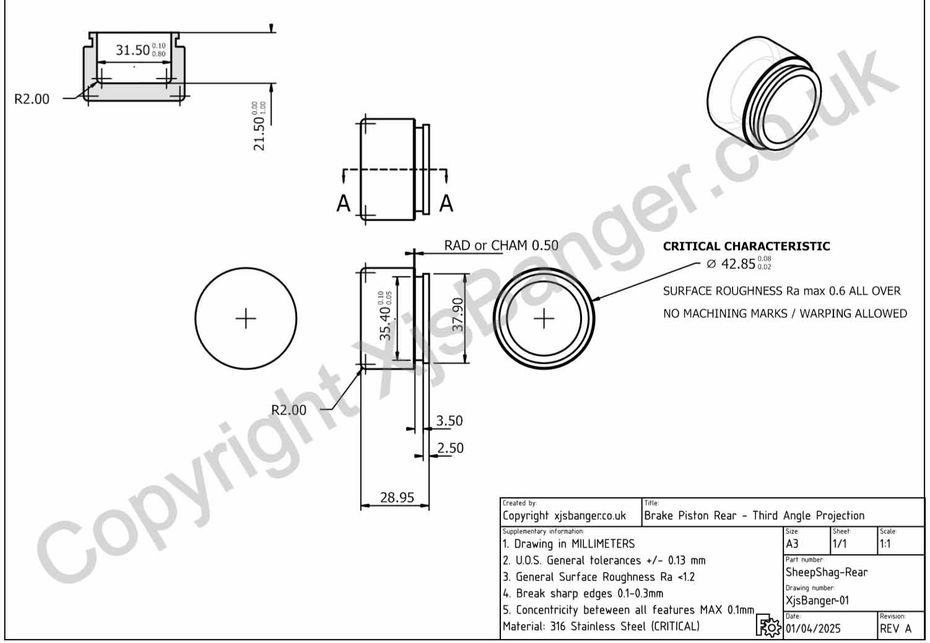

Jaguar XJS Rear Brake Caliper Piston - Blueprint

First thing first – if you don’t know what to do with brake pistons, you don’t understand how the lathe works – have a look at weird drawing and buzz off to Instagram. No, it’s not about cost. It's all about fun and skills, quality outcome. This article is not for old pimps with financial problems / willing to save single coin.

Rear Brake Piston – What Material

Most of you think that tin alloy or zinc is the best material for brake pistons. I must surprise and disappoint you – it is not.

Your genuine XJS brake pistons are made out of mild steel. They look nice as they should be chrome plated. They should be – but they’re not anymore. Instead, various manufacturers are using cheaper or worst “eco-friendly” methods of coating – which is the only barrier between air and metal.

As every child of XJS owner knows, brake piston plating, made by Jaguar in Great Britain was flaking off more severe than lead-based paint from terraced house in Jaywick. That was the actual cause of Brake failures, not the massive, heavy and robust Girling design. Since Jaguars in UK were treated with respect and consideration of Diversity Act – brake problems were noticeable after no pistons left were moving freely in every calliper.

These days, we have a remedy. It’s closer than you think, you can make it bulletproof, maybe even by yourself. The question remains – what material is the best. So let’s have a look at the top picks of bullshit from various Jaguar forums:

1. Titanium

Ultra high-tech material with excellent thermal conductivity used in aerospace, just unbeatable and shiny, so it must be the bes… NAAAAH. It is not the best, actually, it’s not even close being there. It forms oxy layer on the surface, don’t like chlorine and other bits which can cause pitting and surface finish isn’t great same ass the abrasion resistance with rubber seals. It is good for other applications, let’s leave it out there.

2. Aluminium

Some people in Coventry are still making custom replacement pistons from this material. The rumour states – it’s because of the confusion of piston with calliper body. One day, someone will invent brake rotors from this versatile material. But, nope, not the best for our purpose.

3. Stainless Steel

Entirely usual, almost forgotten and the best for this task. Precisely 316 grade. Period.

We have plenty of stainless steel piston manufacturers, if you have to buy those, go for it, but please remember, most of them will provide you with explanations regarding poor surface finish or wide tolerances like these below:

- “surface finish is rough to provide grip for the seals” – just imagine, this came out from poor bastard on Jaguar forum

- “those must have rough surface finish on the OD to allow retract when you release the brake pedal”, absolute BS, this time from Jag-Lovers

- “they are slightly smaller because some callipers have smaller fitting”. Well, another noob-customer bated off.

- “our 303 SS grade is the same as 316 don’t worry” – there is nothing wrong about it, apart from the fact that 303 grade… corrodes.

All above are Bullshit. Do not tolerate or follow anyone who thinks differently. Fully stainless brake pistons for your Jaguar XJS and any other Jag using Girling callipers must be made with satisfactory mirror-like surface finish on OD, made from 316 grade of stainless steel – NOT 303 grade which is easy and quick to machine and corrodes quicker than chrome plated mild steel, especially that the price of the stainless piston version would be 4x higher than classic one. No machining marks allowed.

Now, with the drawing above and machining shop – you can make those for approx. £7 each with batch size of 30. VAT and material included.

If you’re one of those lucky bastards, having a lathe in your workshop – you can go down to the price of material, 316SS round bar is extremely easy to get. Nope, you don’t need to ground those to get perfect finish. Use file sander with ultra-fine belt, then finish with cheap Chinese diamond paste and piece of cloth.